凯利特产品分类

Product Center

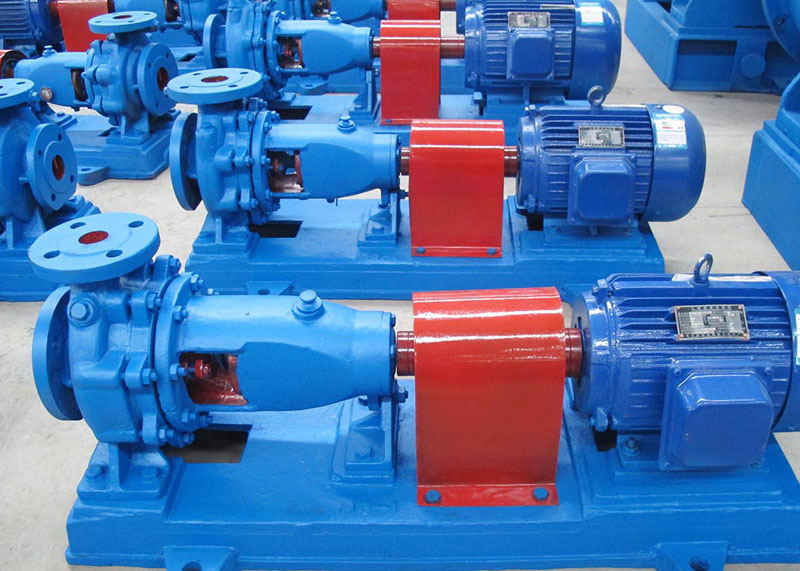

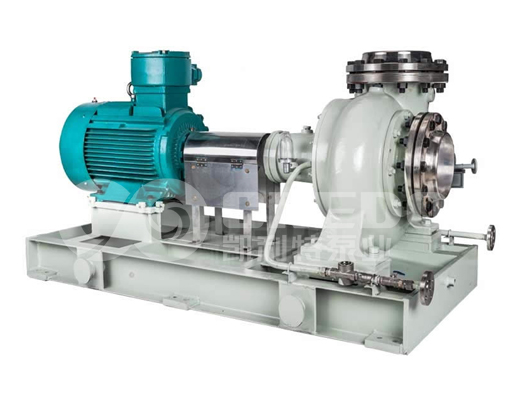

概 述

ZA型化工流程离心泵,按照API610和 VDMA24297(轻/中型)规范而设计、生产的产品。可输送各种温度和浓度的硫酸、硝酸、盐酸和磷酸等无机酸和有机酸溶液;各种温度和浓度的氢氧化钠和碳酸钠等碱性溶液;各种盐溶液;各种液态石油化工产品、有机化合物以及其它有腐蚀性的液体。该型泵适用于炼油厂、石油化学工业煤加工工程、低温工程、造 纸业、制糖业、供水厂、海水淡化厂、发电厂、环保工程和船舶业等。从电动机端看,泵的旋转方向为顺时针方向旋转。

结构特点

该类型的化工流程是采用的标准管路按API规范设计。叶轮可用闭式、半开式、开式三种。可输送清洁,含颗粒,含少量气体介质。也可输送高温、低温、强腐蚀介质。叶轮设有平衡孔加耐腐环,平衡轴向力。泵体和轴承架用中间连接段连接。根据不同的工况条件,中间连接段可采用不同的材质,避免输送强腐蚀介质时轴承架、轴承严重腐蚀。同时中间连接段设有水冷腔,通冷却循环水,阻隔高温介质将高温传到轴承上。密封形式可采用填料密封,单、双端面机械密封,集装式单端面机械密封。根据不同情况和用户对冷却与冲洗要求,密封可按API682设计规范从案中选用。轴承架设计有空冷散热片、风冷风扇、水冷腔三种形式,用户可根据使用工况选用。轴承由油环从油箱里溅稀油润滑。油箱内的油由水冷腔的水冷却,轴承内的热由冷水带走,以保证轴承随时处于正常工作状态。根据介质温度和压力等情况,支撑形式采用中心支撑和脚架支撑。吸入及排出法兰的额定压力等级相同。

型号说明

例:ZA25-200C

ZA——石油化工流程泵

25 ——吐出口直径(mm)

200 —— 叶轮名义直径(mm)

C ——叶轮切割次数,顺序以A,B,C...表示

性能范围(设计点)

口径:25~400mm

流量:5.5~2600m3/h

扬程:16~250m

工作压力:~2.5MPa

工作温度:-80℃ ~ +450℃

可选择的耐腐蚀材料包括303、305、306、307、316、316L、904、904L、804、ECR合金、NiCr合金、哈氏合金、CD-4MnCu及钛合金等,能满足上述各种介质的要求。订货时,请用户提供所要输送介质的详细情况。

受篇幅限制部分型号参数未显示,如需完整参数型号请垂询400-101-0731

|

ZA型化工流程泵 |

叶轮形式 |

流量 |

杨程 |

转速 |

轴功率 |

电机功率 |

电机型号 |

效率 |

必须汽蚀余量 (NPSH)r |

叶轮名义直径 |

|

|

- |

m3/h |

m |

r/min |

KW |

KW |

|

% |

m |

mm |

|

ZA100-160 |

A |

81 |

7.2 |

1475 |

2 |

3 |

Y100L2-4 |

79.5 |

1.5 |

169 |

|

B |

73 |

6 |

1.6 |

2.2 |

Y100L1-4 |

77 |

1.4 |

158 |

||

|

C |

63 |

4.3 |

1 |

1.5 |

Y90L-4 |

74 |

1.2 |

140 |

||

|

D |

55 |

3 |

0.63 |

1.1 |

Y90S-4 |

71 |

1 |

125 |

||

|

ZA100-200 |

A |

95 |

12.5 |

1475 |

4.1 |

5.5 |

Y132S-4 |

79 |

1.1 |

209 |

|

B |

90 |

10.5 |

3.3 |

5.5 |

Y132S-4 |

77 |

1 |

19 |

||

|

C |

80 |

8.5 |

2.5 |

4 |

Y112M-4 |

74 |

0.9 |

180 |

||

|

D |

70 |

6 |

1.6 |

3 |

Y100L2-4 |

71 |

0.9 |

160 |

||

|

ZA100-250 |

A |

115 |

20 |

1475 |

7.9 |

11 |

Y160M-4 |

79.5 |

1.2 |

259 |

|

B |

110 |

18 |

6.8 |

11 |

Y160M-4 |

79 |

1 |

250 |

||

|

C |

100 |

14 |

4.9 |

7.5 |

Y132M-4 |

78 |

1 |

230/220 |

||

|

D |

90 |

10 |

3.2 |

5.5 |

Y132S-4 |

76 |

1 |

205/195 |

||

|

ZA100-315 |

A |

125 |

31 |

1475 |

14.5 |

18.5 |

Y180M-4 |

73 |

1.2 |

324 |

|

B |

119 |

29 |

12.9 |

18.5 |

Y180M-4 |

73 |

1 |

315 |

||

|

C |

104 |

24 |

9.9 |

15 |

Y160L-4 |

69 |

1 |

295/275 |

||

|

D |

83 |

17.5 |

6.1 |

11 |

Y160M-4 |

65 |

1 |

260/240 |

||

|

ZA100-400 |

A |

150 |

48 |

1475 |

28 |

37 |

Y225S-4 |

70 |

1.5 |

409 |

|

B |

145 |

44 |

24.8 |

30 |

Y200L-4 |

70 |

1.4 |

397 |

||

|

C |

130 |

36 |

18.7 |

22 |

Y180L-4 |

68 |

1.4 |

360 |

||

|

D |

115 |

26 |

12.5 |

15 |

Y160L-4 |

65 |

1.5 |

320 |

||

|

ZA100-500 |

A |

180 |

75 |

1475 |

52.5 |

75 |

Y280S-4 |

70 |

1.6 |

514 |

|

B |

167 |

68 |

44.8 |

55 |

Y250M-4 |

69 |

1.5 |

500 |

||

|

C |

142 |

53 |

31.5 |

37 |

Y225S-4 |

65 |

1.5 |

450 |

||

|

D |

120 |

42 |

21.8 |

30 |

Y200L-4 |

63 |

1.5 |

400 |

||

|

ZA150-200 |

A |

160 |

11 |

1475 |

5.8 |

7.5 |

Y132M-4 |

82 |

2 |

209 |

|

B |

152 |

9.5 |

4.9 |

7.5 |

Y132M-4 |

81 |

1.7 |

198 |

||

|

C |

140 |

7 |

3.5 |

5.5 |

Y132S-4 |

76 |

1.5 |

180 |

||

|

D |

123 |

5 |

2.3 |

3 |

Y100L2-4 |

73 |

1.5 |

160 |

||

|

ZA150-250 |

A |

195 |

18.5 |

1475 |

12.2 |

15 |

Y160L-4 |

80.5 |

1.5 |

259 |

|

B |

180 |

16 |

10.1 |

15 |

Y160L-4 |

78 |

1.4 |

240 |

||

|

C |

160 |

11.5 |

6.7 |

11 |

Y160M-4 |

75 |

1.4 |

220/205 |

||

|

ZA150-315 |

A |

220 |

32.5 |

1475 |

24 |

30 |

Y200L-4 |

81 |

1.8 |

324 |

|

B |

210 |

30 |

21.4 |

30 |

Y200L-4 |

80 |

1.8 |

315 |

||

|

C |

180 |

24 |

15.5 |

22 |

Y180L-4 |

76 |

1.5 |

285 |

||

|

D |

150 |

17 |

9.6 |

15 |

Y160L-4 |

72 |

1.4 |

250 |

||

|

ZA150-400 |

A |

260 |

51 |

1475 |

46.9 |

55 |

Y250M-4 |

77 |

1.8 |

409 |

|

B |

250 |

48 |

42.4 |

55 |

Y250M-4 |

77 |

1.7 |

397 |

||

|

C |

225 |

38 |

31 |

37 |

Y225S-4 |

75 |

1.6 |

365/355 |

||

|

D |

200 |

28 |

21.2 |

30 |

Y200L-4 |

72 |

1.5 |

330/310 |

||

|

ZA150-500 |

A |

300 |

77 |

1475 |

85 |

110 |

Y315S-4 |

74 |

2 |

514 |

|

B |

283 |

72 |

75 |

90 |

Y280M-4 |

74 |

1.8 |

500 |

||

|

C |

233 |

59 |

52 |

75 |

Y280S-4 |

72 |

1.8 |

450 |

||

|

D |

208 |

45 |

36.4 |

45 |

Y225M-4 |

70 |

2 |

400 |

||

|

ZA150-560 |

A |

335 |

104 |

1475 |

135 |

16 |

Y315L1-4 |

74.5 |

2.5 |

578 |

|

B |

315 |

97 |

112 |

132 |

Y315M-4 |

74 |

2.3 |

560 |

||

|

C |

260 |

80 |

78.7 |

90 |

Y280M-4 |

72 |

2.3 |

510 |

||

|

D |

212 |

60 |

52.5 |

75 |

Y280S-4 |

66 |

2.5 |

450 |

||

|

ZA150-630 |

A |

360 |

115 |

1475 |

179 |

220 |

Y355M1-4 |

63 |

2.5 |

648 |

|

B |

338 |

105.5 |

157 |

185 |

Y315L-4 |

62 |

2.2 |

630 |

||

|

C |

274 |

82 |

104 |

132 |

Y315M-4 |

59 |

1.8 |

570 |

||

|

D |

220 |

60 |

64.2 |

75 |

Y280S-4 |

56 |

2.2 |

500 |

||

|

ZA200-250 |

A |

305 |

17.5 |

1475 |

17.4 |

22 |

Y180L-4 |

83.5 |

2.5 |

259 |

|

B |

290 |

16 |

15.2 |

18.5 |

Y180M-4 |

83 |

2 |

250 |

||

|

C |

260 |

12 |

10.5 |

15 |

Y160L-4 |

81 |

1.8 |

225 |

||

|

D |

240 |

8 |

6.6 |

11 |

Y160M-4 |

79 |

1.6 |

200 |

||

|

ZA200-315 |

A |

350 |

30 |

1475 |

33.8 |

45 |

Y225M-4 |

84.5 |

2.2 |

324 |

|

B |

340 |

29 |

32 |

37 |

Y225S-4 |

84 |

2 |

315 |

||

|

C |

300 |

22 |

22.8 |

30 |

Y200L-4 |

79 |

2 |

285 |

||

|

D |

250 |

15 |

13.4 |

18.5 |

Y180M-4 |

76 |

2 |

250 |

||

|

ZA200-400 |

A |

426 |

50 |

1475 |

71.6 |

90 |

Y280M-4 |

81 |

3.5 |

409 |

|

B |

410 |

47 |

65.6 |

75 |

Y280S-4 |

80 |

3.2 |

397 |

||

|

C |

370 |

36.5 |

47.2 |

55 |

Y250M-4 |

78 |

2.5 |

360 |

||

|

D |

332 |

27 |

32.5 |

45 |

Y225M-4 |

75 |

2.5 |

320 |

||

|

ZA200-500 |

A |

495 |

84 |

1475 |

140 |

185 |

Y315L-4 |

81 |

3 |

514 |

|

B |

470 |

79 |

126 |

160 |

Y315L1-4 |

80 |

2.6 |

500 |

||

|

C |

400 |

63 |

89.1 |

110 |

Y315S-4 |

77 |

2.1 |

450 |

||

|

D |

330 |

48 |

58.3 |

75 |

Y280S-4 |

74 |

2.5 |

400 |

||

|

ZA200-560 |

A |

540 |

105 |

1475 |

194 |

220 |

Y355M1-4 |

79.5 |

3.1 |

578 |

|

B |

510 |

98 |

172 |

220 |

Y355M1-4 |

79 |

3 |

560 |

||

|

C |

440 |

81 |

128 |

160 |

Y315L1-4 |

76 |

2.5 |

500 |

||

|

D |

350 |

62 |

81 |

110 |

Y315S-4 |

73 |

2.5 |

450 |

||

|

ZA200-630 |

A |

580 |

132 |

1475 |

269 |

315 |

Y355L2-4 |

77.5 |

3.5 |

648 |

|

B |

550 |

125 |

245 |

280 |

Y355L1-4 |

76.5 |

3.2 |

630 |

||

|

C |

468 |

100 |

175 |

220 |

Y355M1-4 |

73 |

2.5 |

570 |

||

|

D |

372 |

75 |

109 |

132 |

Y315M-4 |

70 |

2.5 |

500 |

||

|

ZA250-315 |

A |

545 |

27 |

1475 |

46.9 |

55 |

Y250M-4 |

85.5 |

3.1 |

324 |

|

B |

528 |

25 |

42.3 |

55 |

Y250M-4 |

85 |

2.8 |

315 |

||

|

C |

480 |

19 |

30.3 |

37 |

Y225S-4 |

82 |

2.5 |

285 |

||

|

D |

434 |

13 |

20 |

30 |

Y200L-4 |

77 |

2.8 |

250 |

||

|

ZA250-400 |

A |

660 |

49 |

1475 |

105 |

132 |

Y315M-4 |

84 |

4 |

409 |

|

B |

630 |

46 |

96.2 |

110 |

Y315S-4 |

82 |

3.5 |

397 |

||

|

C |

565 |

36 |

68.4 |

75 |

Y280S-4 |

81 |

3.2 |

370/350 |

||

|

D |

500 |

24 |

42.4 |

55 |

Y250M-4 |

77 |

3.2 |

330/310 |

||

|

ZA250-500 |

A |

800 |

82 |

1475 |

215 |

250 |

Y355M2-4 |

83 |

5 |

514 |

|

B |

770 |

76 |

194 |

250 |

Y355M2-4 |

82 |

4.8 |

500 |

||

|

C |

700 |

58 |

138 |

160 |

Y315L1-4 |

80 |

4.5 |

460/440 |

||

|

D |

630 |

42 |

94.8 |

110 |

Y315S-4 |

76 |

5.6 |

415/385 |

||

|

ZA250-560 |

A |

860 |

106 |

1475 |

308 |

355 |

|

80.5 |

5 |

648 |

|

B |

830 |

98 |

277 |

355 |

|

80 |

4.8 |

630 |

||

|

C |

760 |

78 |

208 |

250 |

Y355M2-4 |

77.5 |

3.6 |

570 |

||

|

D |

665 |

57 |

136 |

160 |

Y315L1-4 |

76 |

3 |

500 |

||

|

ZA250-630 |

A |

855 |

128 |

1475 |

370 |

450 |

|

80.5 |

5 |

648 |

|

B |

816 |

119 |

331 |

400 |

|

80 |

4.5 |

630 |

||

|

C |

720 |

96 |

241 |

280 |

Y355L1-4 |

78 |

3.5 |

570 |

||

|

D |

625 |

71 |

1475 |

159 |

200 |

Y315L2-4 |

76 |

3 |

500 |

|

|

ZA300-400 |

A |

1050 |

48 |

1475 |

158 |

200 |

Y315L2-4 |

87 |

6 |

409 |

|

B |

1010 |

45 |

144 |

185 |

Y315L-4 |

86 |

5.2 |

397 |

||

|

C |

900 |

34 |

100 |

132 |

Y315M-4 |

83 |

4.5 |

370/350 |

||

|

D |

780 |

26 |

70.8 |

90 |

Y280M-4 |

78 |

4.5 |

337/310 |

||

|

ZA300-500 |

A |

1240 |

78 |

1475 |

299 |

355 |

|

88 |

5 |

514 |

|

B |

1170 |

75 |

272 |

315 |

Y355L2-4 |

88 |

4.7 |

500 |

||

|

C |

1050 |

57 |

190 |

250 |

Y355M2-4 |

86 |

4.5 |

450 |

||

|

D |

870 |

42 |

124 |

160 |

Y315L1-4 |

80 |

4.5 |

400 |

||

|

ZA300-560 |

A |

1340 |

104 |

1475 |

436 |

500 |

|

87 |

5.5 |

578 |

|

B |

1280 |

97 |

393 |

500 |

|

86 |

4.8 |

560 |

||

|

C |

1140 |

77 |

288 |

355 |

|

83 |

4.5 |

510 |

||

|

D |

950 |

56 |

181 |

220 |

Y355M1-4 |

80 |

4.5 |

450 |

||

|

ZA300-630 |

A |

1450 |

132 |

1475 |

613 |

710 |

|

85 |

5.8 |

648 |

|

B |

1375 |

125 |

557 |

710 |

|

84 |

5.2 |

630 |

||

|

C |

1170 |

100 |

389 |

450 |

|

82 |

4.5 |

570 |

||

|

D |

950 |

75 |

255 |

315 |

Y355L2-4 |

76 |

4.5 |

500 |

||

|

ZA400-500 |

A |

1900 |

74 |

1475 |

435 |

500 |

|

88 |

7 |

514 |

|

B |

1800 |

70 |

394 |

450 |

|

87 |

6 |

500 |

||

|

C |

1600 |

52 |

270 |

355 |

|

84 |

5.5 |

450 |

||

|

D |

1320 |

38 |

171 |

220 |

Y355M1-4 |

80 |

5.5 |

400 |

||

|

ZA400-560 |

A |

2040 |

98 |

1475 |

619 |

710 |

|

88 |

7.8 |

578 |

|

B |

1950 |

91 |

555 |

630 |

|

87 |

7 |

560 |

||

|

C |

1760 |

74 |

412 |

500 |

|

86 |

5 |

510 |

||

|

D |

1500 |

54 |

269 |

315 |

Y355L2-4 |

82 |

5 |

450 |

||

|

ZA400-630 |

A |

2390 |

125 |

1475 |

925 |

1120 |

|

88 |

9 |

648 |

|

B |

2280 |

117 |

826 |

1000 |

|

88 |

8 |

630 |

||

|

C |

1960 |

95 |

597 |

710 |

|

85 |

6 |

570 |

||

|

D |

1610 |

70 |

384 |

450 |

|

80 |

6 |

500 |

推荐新闻

- 凯利特泵业全面复工!2020-03-20

- 2020凯利特泵业新年祝福2020-01-20

- 双吸泵滚动轴承怎么选?2016-05-20

- 双吸泵滚动轴承运转时出现异常响声的原因有哪些?2016-05-20

- 双吸离心泵在什么情况下应紧急停车?2016-05-20

- 双吸离心泵运行时应注意哪些事项?2016-05-20

- 什么是双吸离心泵的临界转速?2016-05-20

- 双吸泵叶轮口环间隙过大或过小会出现什么问题?2016-05-20

- 双吸离心泵在操作过程中怎样防止抽空、汽蚀现象出现...2016-05-20

- 双吸泵房管理人员日常巡检该做哪些事?2016-05-20